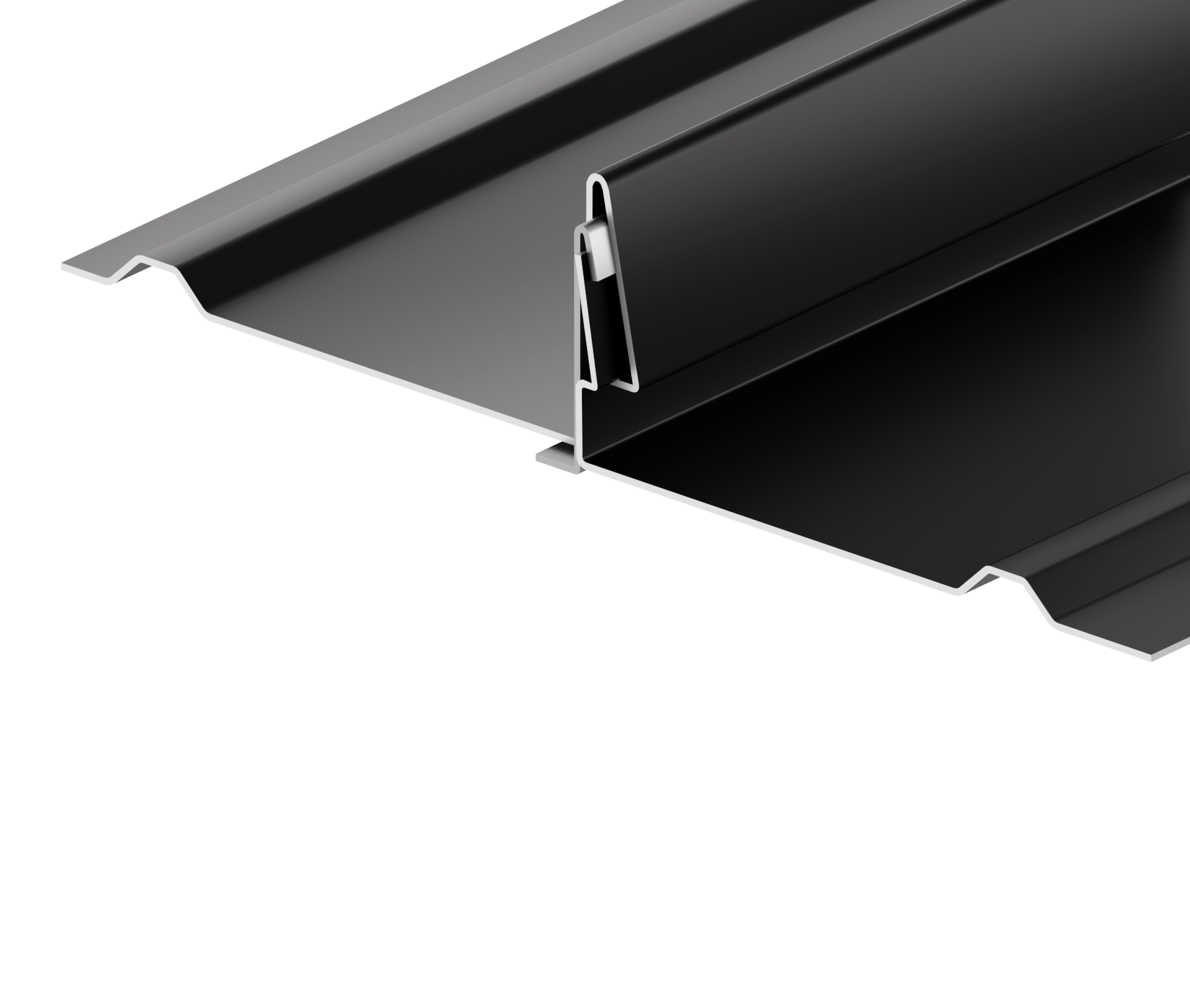

Our Architectural Metal Roof Panel Systems are designed for maximum durability and performance. They are rigorously tested, including ASTM water and air testing, ASTM-E84 for Class A fire rating, and ASTM-E1592 for wind resistance. Certified to meet UL 580 Class 90 standards, Dade County approval, and Florida building code compliance, these panels also pass FM testing, ensuring reliable protection in even the toughest conditions.

B&B Sheet Metal's B-Series Architectural Metal Roof Panels meet the strictest ASTM standards, ensuring top-tier performance. Our panels are rigorously tested for durability and comply with ASTM standards for water, air, and fire resistance, achieving a Class A fire rating. They are UL 580 Class 90 certified, Dade County tested, and Florida building code compliant. With weather tightness warranties, these panels are built to provide long-lasting protection and reliability.

B&B Sheet Metal's Architectural Metal Roof Panels meet the strictest ASTM standards, ensuring top-tier performance. Our panels are rigorously tested for durability and comply with ASTM standards for w...

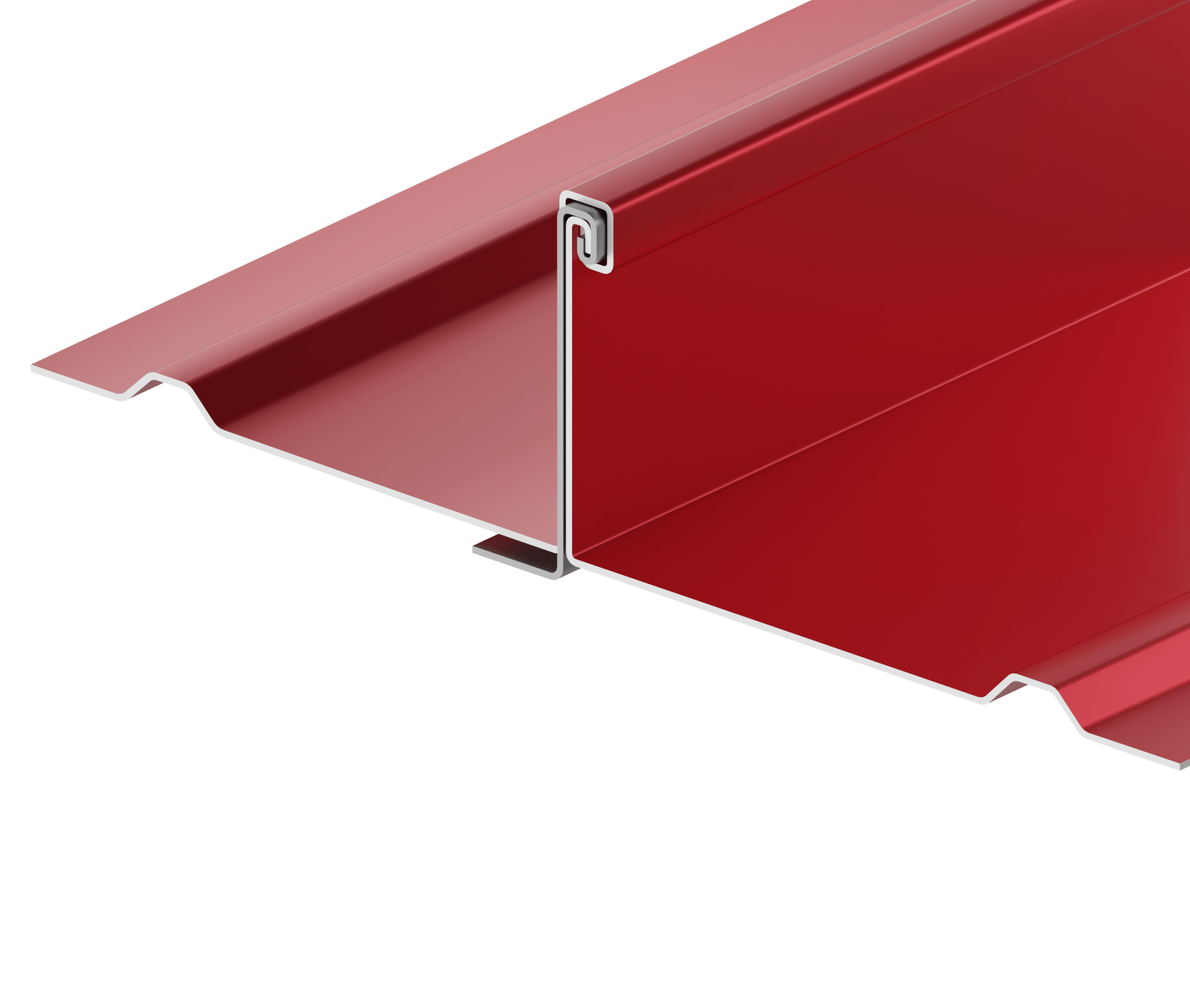

View ProductB&B Sheet Metal's BB-Structural metal roof panel systems undergo rigorous testing to meet top industry standards, including ASTM tests for water, air, and fire resistance (Class A rating) and ASTM-E1592 for strength. They are UL 580 Class 90 certified, Dade County tested, and compliant with Florida building codes. Additionally, these panels are FM tested for enhanced quality assurance. Backed by weather tightness warranties, they offer reliable performance and long-lasting durability in all conditions.

ASTM water & air tested ASTM-E84 tested (Class A Fire rating) ASTM-E1592 tested UL 580, Class 90 Dade county tested Florida building code compliant FM tested

View ProductB&B Sheet Metal standing seam roofs are available in a variety of materials, with copper, zinc, Kynar-coated steel, and aluminum being popular choices. Our advanced production facility allows us to deliver complete solutions in all materials, ensuring top-quality results. Using our longfolder, we can taper panels up to 26 feet in length and fabricate custom starter and finish pieces in extended sizes. This streamlines installation and provides a higher quality, more efficient product.

B&B Sheet Metal’s Series B1301/B1300 presents the same architectural aesthetics as the architectural snap-lockpanels except with structural strength and weather tightness advantage of a mechanically...

View Product

B&B Sheet Metal’s batten seam roofing comes in a wide variety of shapes...

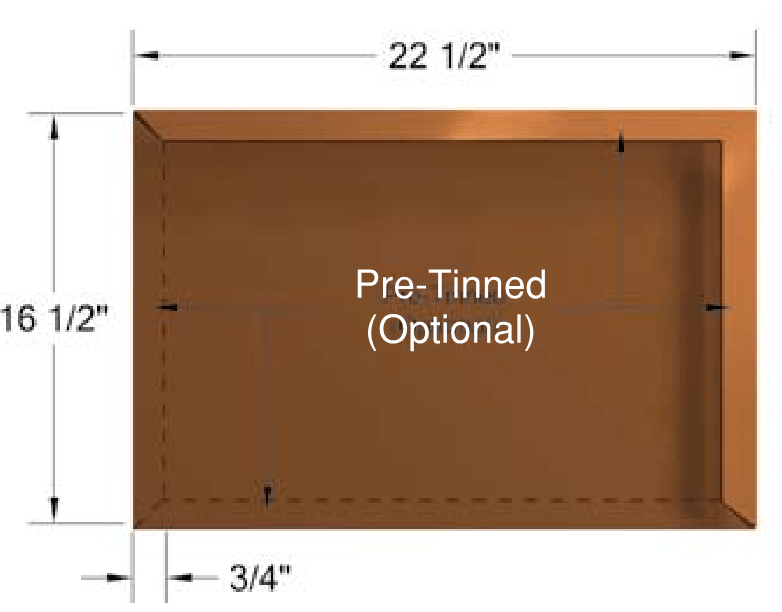

View ProductTinned flat seam roof panels are thin, interlocking metal sheets that create a sleek, low-profile roofing surface. Made from durable materials like stainless steel, copper, or galvanized steel, they offer strong corrosion resistance and long-lasting performance. These panels are particularly suited for roofs with low slopes or intricate designs, as their interlocking seams provide a watertight barrier. Commonly used in historic restorations and modern architecture, tinned flat seam panels are ideal for areas with challenging weather due to their durability and aesthetic versatility.

B&B Sheet Metal’s Flat & Diamond Flat seam panels are manufactured by turning up the intersecting seams up, folding over, and flattening the joints by soldering. Flat & Diamond Flat seam roofing sys...

View Product